Table of Contents

- Understanding the Origins and Significance of Gaia Iron

- Exploring the Unique Composition of Gaia Iron

- Applications and Benefits of Gaia Iron in Modern Industries

- Environmental Impact and Sustainable Practices in Gaia Iron Production

- Expert Recommendations for Integrating Gaia Iron in Projects

- Q&A

- In Conclusion

Understanding the Origins and Significance of Gaia Iron

Gaia Iron, a term often associated with ecological harmony and balance, draws its name from Gaia, the ancient Greek goddess representing Earth as a nurturing mother. Its origins can be traced back to indigenous metallurgy practices where blacksmiths respected the cycles of nature. At its core, Gaia Iron embodies sustainability and innovation, two principles that were central to early Earth-centered cultures. Unlike conventional iron, which often prioritizes industrial efficiency, Gaia Iron places emphasis on environmental ethics and conscientious use of resources. This philosophy has evolved into a movement striving to maintain ecological balance while fostering technological advancement.

The significance of Gaia Iron extends beyond mere material innovation. It serves as a symbol of a growing recognition of sustainable practices in the iron industry. Over the years, notable attributes of Gaia Iron that resonate with ecologists and artisans alike include:

- Eco-friendly Production: Methods that minimize carbon footprint.

- Durability: Enhanced lifespan through special alloy combinations.

- Recyclability: Promotes a circular economy approach.

- Aesthetic Appeal: Unique textures and patterns that reflect natural beauty.

| Characteristic | Gaia Iron | Traditional Iron |

|---|---|---|

| Carbon Footprint | Low | High |

| Recyclability | High | Moderate |

| Lifespan | Extended | Standard |

This conscious shift towards embracing earth-positive materials like Gaia Iron signifies a paradigm change in how we perceive and utilize natural resources. Its influence is witnessing a rise in various industries—from architecture to art—as stakeholders increasingly opt for materials harmonizing with both form and function. As part of a broader earth-centric philosophy, Gaia Iron enables creators to not only fulfill their vision but also contribute to a more sustainable future, making it quintessential in the dialogue between technology and environmental stewardship.

Exploring the Unique Composition of Gaia Iron

Gaia Iron, renowned for its exceptional durability and flexibility, boasts a composition that intrigues scientists and artisans alike. This metal is an alloy of several key elements that contribute to its remarkable properties. Chief among them is titanium, known for its strength-to-weight ratio, making Gaia Iron lighter yet stronger than conventional metals. In addition to titanium, nickel is incorporated, adding to its corrosion resistance, which enables the metal to withstand harsh environments and prolonged exposure without deteriorating.

Another fascinating aspect of this metal is its inclusion of rare earth elements, such as lanthanum and neodymium. These rare earths are treasured for their ability to enhance the alloy’s magnetic properties. Combined with expertly engineered quantities of carbon, Gaia Iron achieves a finely-tuned balance of hardness and elasticity, positioning it as an ideal candidate for applications requiring resilience and adaptability. The synergy between these materials results in a metal that is not only practical but also cost-effective, maintaining its performance over long periods.

- Primary Components: Titanium, Nickel

- Enhancement Elements: Lanthanum, Neodymium

- Structural Additives: Carbon

To fully grasp the uniqueness of Gaia Iron, it’s insightful to look at its comparative composition through a simple table, facilitating a quick understanding of its specialized nature:

| Element | Contribution |

|---|---|

| Titanium | Strength and lightweight |

| Nickel | Corrosion resistance |

| Lanthanum | Magnetic enhancement |

| Carbon | Hardness and flexibility |

The strategic arrangement of these elements is what makes Gaia Iron truly a marvel in the world of metallurgy. Each component is selected not just for its individual qualities but for the transformative power of their combination, leading to innovations across multiple industries, from automotive to aerospace engineering.

Applications and Benefits of Gaia Iron in Modern Industries

Embracing the versatility of Gaia Iron is crucial for different sectors that demand robust and sustainable solutions. In the automotive industry, this innovative material is redefining production standards. Its lightweight nature, coupled with remarkable strength, makes it an excellent choice for vehicle components, allowing manufacturers to enhance fuel efficiency and reduce carbon emissions. Furthermore, Gaia Iron’s corrosion-resistant properties prolong the lifespan of auto parts, ensuring reliability in diverse environmental conditions. This makes it an indispensable asset in developing electric vehicles, where durability and sustainability are priorities.

The construction industry, too, benefits significantly from the strategic use of Gaia Iron. Its ability to withstand structural stress while retaining flexibility under varying loads contributes to safer, more resilient buildings. Sustainable construction practices increasingly favor Gaia Iron due to its eco-friendly production processes and potential for recycling. Key applications include:

- Structural frameworks for skyscrapers

- Reinforced support beams

- Foundation elements

- Bridge components

In the realm of high-tech industries, Gaia Iron is making waves by enabling advancements across multiple technologies. Its exceptional thermal conductivity is ideal for use in electronics and cooling systems. Moreover, Gaia Iron is at the forefront of sustainable energy solutions; when integrated into wind turbine technology, it supports the production of robust yet light-weight turbines. This significantly increases the efficiency of energy capture, making Gaia Iron a keystone in the evolving landscape of renewable energy sources.

| Industry | Key Benefit | Example Usage |

|---|---|---|

| Automotive | Improved Efficiency | Lightweight Vehicle Panels |

| Construction | Sustainability | Architectural Frameworks |

| Technology | Enhanced Performance | High-performance Electronics |

Environmental Impact and Sustainable Practices in Gaia Iron Production

The production of Gaia Iron has taken significant strides in minimizing its ecological footprint. Central to this endeavor is the integration of cutting-edge renewable energy sources. Solar and wind power facilities are strategically located near the production sites, dramatically reducing dependence on fossil fuels. This not only lowers greenhouse gas emissions but also aligns with the global targets for sustainable energy use in industrial operations. Additionally, the adoption of advanced technologies for waste heat recovery ensures that no energy is wasted, further enhancing the sustainability of the manufacturing processes.

Gaia Iron maintains its commitment to environmental stewardship through meticulous resource management practices. This includes the responsible sourcing of raw materials, ensuring that mining activities do not lead to irreversible environmental damage. By employing innovative recycling techniques, the company minimizes the need for virgin raw materials, resulting in less disruption to natural landscapes. Key elements of their approach include:

- Efficient water usage and recycling systems

- Commitment to biodiversity conservation

- Implementation of zero-waste manufacturing protocols

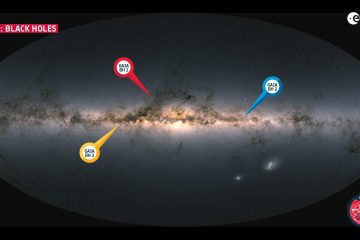

To consistently measure and improve their sustainable practices, Gaia Iron employs a robust monitoring framework. The company’s sustainability metrics are tracked using a sophisticated system which includes regular audits and assessments, ensuring transparency and accountability. Progress is documented and shared in annual sustainability reports, allowing stakeholders to stay informed about the environmental impact and future eco-friendly endeavors. A snapshot of critical performance indicators is illustrated below:

| Metric | 2022 | 2023 |

|---|---|---|

| CO2 Emissions Reduction | 15% | 20% |

| Energy from Renewables | 30% | 40% |

| Recycled Materials Utilization | 25% | 35% |

Expert Recommendations for Integrating Gaia Iron in Projects

The integration of Gaia Iron into your projects requires a strategic approach that balances innovation with practicality. Architects and designers often find great value in leveraging this versatile material, thanks to its enduring durability and aesthetic appeal. Start by evaluating the specific requirements of your project, particularly the environmental conditions it will face. Gaia Iron’s corrosion-resistant properties make it a prime candidate for outdoor installations and structures exposed to harsh weather conditions.

When planning the use of this material, consider collaborating with local artisans and metalworkers who have experience working with Gaia Iron. Their insights can be invaluable, as they offer creative solutions and customization options that can enhance your project’s uniqueness. Engage these experts early in the design phase to maximize the potential of Gaia Iron and explore innovative applications that might otherwise be overlooked. They can assist in coordinating logistics and managing potential challenges associated with handling and integrating the material.

To streamline the integration process, implement a straightforward checklist strategy:

- Material Assessment: Verify the suitability of Gaia Iron for your intended project.

- Supplier Coordination: Establish relationships with trusted suppliers for consistent material quality.

- Site Evaluation: Conduct thorough site assessments to ensure compatibility.

| Step | Action | Outcome |

|---|---|---|

| Design | Collaborate with experts | Innovative use of Gaia Iron |

| Procurement | Source from reliable suppliers | Quality assurance maintained |

| Installation | Follow predefined checklist | Seamless integration |

0 Comments